Lesitala i la Matou Ala o Faasalalauga Lautele mo se Pou Vave

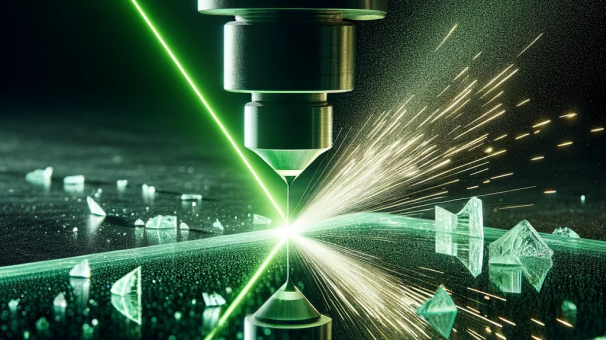

Fa'atomuaga i le Fa'agasologa o le Laser i le Gaosiga

Ua vave ona atina'eina le tekinolosi o le fa'agasologa o le laser ma ua fa'aaogaina lautele i le tele o vaega, e pei o le va'alele, ta'avale, eletise, ma isi mea. E taua tele lona sao i le fa'aleleia atili o le lelei o oloa, le gaosiga o le aufaigaluega, ma le otometi, a'o fa'aitiitia ai le fa'aleagaina o le ea ma le fa'aaogaina o meafaitino (Gong, 2012).

Fa'agasologa o le Laser i Mea U'amea ma Mea e lē o ni U'amea

O le faʻaaogaina autū o le faʻagasologa o le laser i le sefulu tausaga ua tuanaʻi o mea uʻamea, e aofia ai le tipiina, faʻapipiʻiina, ma le ufiufi. Peitaʻi, o loʻo faʻalauteleina le matata i mea e le o ni uʻamea e pei o ie, tioata, palasitika, polymers, ma seramika. O nei mea taʻitasi e tatala ai avanoa i pisinisi eseese, e ui lava ua i ai a latou metotia faʻagasologa ua faʻatuina (Yumoto et al., 2017).

Luʻitau ma Fouga Fou i le Faʻagasologaina o Tioata i le Laser

O tioata, faatasi ai ma ona faʻaoga lautele i alamanuia e pei o taavale, fausiaina, ma mea eletise, o se vaega taua mo le faʻagasologaina o le laser. O auala masani e tipi ai tioata, e aofia ai meafaigaluega uʻamea malo poʻo taimane, e faʻatapulaʻaina e le lelei maualalo ma pito maʻaʻa. I se faʻatusatusaga, o le tipiina o le laser e ofoina atu ai se isi auala e sili atu ona lelei ma saʻo. E sili atu ona manino lenei mea i alamanuia e pei o le gaosiga o telefonipoto, lea e faʻaaogaina ai le tipiina o le laser mo ufi tioata o le meapueata ma laupepa tetele (Ding et al., 2019).

Fa'agasologaina o le Laser o Ituaiga Tioata Taua Tele

O ituaiga tioata eseese, e pei o tioata opitika, tioata kuata, ma tioata safaira, e iai ni luʻitau tulaga ese ona o lo latou natura maaleale. Peitaʻi, o metotia faʻaonaponei o le laser etching e pei o le femtosecond laser etching ua mafai ai ona faʻagasolo lelei nei mea (Sun & Flores, 2010).

Aafiaga o le Umi o le Galu i luga o Faiga Fa'atekinolosi Laser

O le galu o le laser e matuā aʻafia ai le faagasologa, aemaise lava mo meafaitino e pei o le uʻamea fausaga. O laser e faʻasalalauina i le ultraviolet, vaʻaia, vaega infrared lata ane ma mamao ua uma ona suʻesuʻeina mo lo latou malosi taua mo le faʻamaluluina ma le faʻamamago (Lazov, Angelov, & Teirumnieks, 2019).

Fa'aoga Eseese e Fa'avae i luga o le Umi o Galu

O le filifiliga o le galu o le laser e lē o se mea e fa'afuase'i ae e fa'alagolago tele i meatotino o le meafaitino ma le i'uga e mana'omia. Mo se fa'ata'ita'iga, o le UV lasers (e pupuu galu) e sili ona lelei mo le vaneina ma le fa'amamago sa'o ma le micromachining, aua e mafai ona latou gaosia ni fa'amatalaga sili atu ona lelei. O lenei mea e fetaui lelei ai mo pisinisi semiconductor ma microelectronics. I se fa'atusatusaga, o le infrared lasers e sili atu ona lelei mo le fa'agasologa o meafaitino mafiafia ona o lo latou gafatia loloto o le fa'asusu, ma avea ai ma mea e talafeagai mo galuega mamafa tau alamanuia. (Majumdar & Manna, 2013). I se tulaga fa'apena, o le lasers lanumeamata, e masani ona fa'agaoioia i le galu o le 532 nm, e maua ai lo latou tulaga i galuega e mana'omia ai le sa'o maualuga ma le itiiti o le a'afiaga o le vevela. E aoga tele i le microelectronics mo galuega e pei o le mamanu o matagaluega, i galuega fa'afoma'i mo faiga e pei o le photocoagulation, ma i le vaega o le malosiaga fa'afouina mo le gaosiga o le solar cell. O le galu tulaga ese o le lasers lanumeamata e fetaui lelei ai foi mo le fa'ailogaina ma le vaneina o meafaitino eseese, e aofia ai palasitika ma u'amea, lea e mana'omia ai le eseesega maualuga ma le itiiti o le fa'aleagaina o luga. O lenei fetu'una'iga o le lasers lanumeamata e fa'amamafaina ai le taua o le filifilia o galu i tekinolosi laser, ma fa'amautinoa ai taunuuga sili ona lelei mo meafaitino ma fa'aoga fa'apitoa.

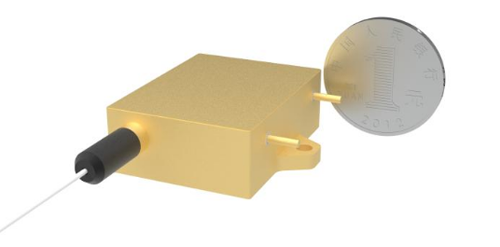

O le525nm leisa lanumeamatao se ituaiga faapitoa o tekinolosi laser e iloga i lona fa'asalalauina o le malamalama lanumeamata i le galu o le 525 nanometers. O laser lanumeamata i lenei galu e maua ai fa'aoga i le retinal photocoagulation, lea e aoga ai lo latou malosi maualuga ma le sa'o. E ono aoga foi i le fa'agasologa o meafaitino, aemaise lava i fanua e mana'omia ai le fa'agasologa sa'o ma le itiiti o le a'afiaga o le vevela..O le atina'eina o diodes laser lanumeamata i luga o le c-plane GaN substrate agai i galu uumi i le 524–532 nm o lo'o fa'ailogaina ai se alualu i luma taua i tekinolosi laser. O lenei atina'e e taua tele mo fa'aoga e mana'omia ai uiga fa'apitoa o galu.

Galu Fa'aauau ma Punaoa o le Laser Fa'ata'ita'i

O le peau faifai pea (CW) ma le modellocked quasi-CW laser sources i galu eseese e pei o le near-infrared (NIR) i le 1064 nm, lanumeamata i le 532 nm, ma le ultraviolet (UV) i le 355 nm ua mafaufauina mo le fa'aaogaina o le laser i le selective emitter solar cells. O galu eseese e iai ni a'afiaga i le fetu'una'iga ma le lelei o le gaosiga (Patel et al., 2011).

Excimer Lasers mo Meafaitino o le Wide Band Gap

O leisa Excimer, e fa'agaoioia i le galu UV, e talafeagai mo le fa'agaoioia o mea e lautele le va o le bandgap e pei o le tioata ma le polymer e fa'amalosia i le carbon fiber (CFRP), e ofoina atu le sa'o maualuga ma le la'ititi o le a'afiaga o le vevela (Kobayashi et al., 2017).

Nd:YAG Lasers mo Galuega Fa'apisinisi

O leisa Nd:YAG, faatasi ai ma lo latou fetuutuunai i tulaga o le fetuutuuna'i o le galu, e fa'aaogaina i le tele o fa'aoga. O lo latou gafatia e fa'agaoioia i le 1064 nm ma le 532 nm e mafai ai ona fetu'una'i i le fa'agaioiga o meafaitino eseese. Mo se fa'ata'ita'iga, o le galu 1064 nm e fetaui lelei mo le vaneina loloto i luga o u'amea, ae o le galu 532 nm e maua ai le vaneina maualuga i luga o palasitika ma u'amea ua ufiufiina. (Moon et al., 1999).

→Oloa Fesoota'i:CW Diode-pumped solid-state laser ma le 1064nm wavelength

Fa'avevela o le Alava Laser Malosiaga Maualuga

O leisa e latalata i le 1000 nm le umi o galu, e lelei le tulaga o le ave ma le malosi tele, e fa'aaogaina i le keyhole laser welding mo u'amea. O nei leisa e fa'amamago lelei ma fa'a'asu ai mea, ma maua ai ni welding lelei (Salminen, Piili, & Purtonen, 2010).

Tuufaatasia o le Faagasologa o le Laser ma Isi Tekonolosi

O le tu'ufa'atasia o le fa'agasologa o le laser ma isi tekinolosi gaosiga, e pei o le ufiufi ma le milling, ua i'u ai i ni faiga gaosiga e sili atu ona lelei ma eseese. O lenei tu'ufa'atasiga e matua'i aoga lava i alamanuia e pei o le gaosiga o meafaigaluega ma die ma le toe fa'aleleia o afi (Nowotny et al., 2010).

Fa'agasologa o le Laser i Matā'upu Fou

O le faʻaaogaina o tekinolosi laser e faʻalautele atu i matāʻupu fou e pei o semiconductor, display, ma industries thin film, e ofoina atu ai ni agavaʻa fou ma faʻaleleia atili ai meatotino o meafaitino, saʻo o oloa, ma le faʻatinoga o masini (Hwang et al., 2022).

Agaifanua i le Lumanai i le Fa'agasologa o le Laser

O atina'e i le lumana'i i tekinolosi fa'agasologa laser e taula'i i metotia fou o le gaosiga, fa'aleleia atili o uiga o oloa, fa'ainisinia o vaega e tele-mea e tu'ufa'atasia ma fa'aleleia atili ai fa'amanuiaga tau tamaoaiga ma fa'atinoga. E aofia ai le gaosiga vave o fausaga i le laser ma le porosity pulea, fa'apipi'i fa'afefiloi, ma le tipiina o pepa u'amea i le laser (Kukreja et al., 2013).

O le tekinolosi o le fa'agasologa o le laser, fa'atasi ai ma ona fa'aoga eseese ma fa'afouga faifai pea, o lo'o fa'atulagaina ai le lumana'i o le gaosiga ma le fa'agasologa o meafaitino. O lona faigofie ma le sa'o e avea ai ma meafaigaluega taua tele i le tele o alamanuia, ma tuleia ai tapula'a o metotia masani o gaosiga.

Lazov, L., Angelov, N., & Teirumnieks, E. (2019). FAIGA MO LE FUAFUAGA MUAMUA O LE MALOSIAGA TAUA I FAIGA FA'ATEKINOLOSI LASER.SI'OSI'OMAGA. TEKINOLOSI. PUNA'OA. Taualumaga o le Konafesi Fa'asaienisi ma Galuega Fa'atino Fa'avaomalo. So'otaga

Patel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., & Bovatsek, J. (2011). Fa'agaoioiga Saosaoa Maualuga o Sela La Selective Emitter e Fa'aaoga ai le 532nm Continuous Wave (CW) ma Modellocked Quasi-CW Laser Sources.So'otaga

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). DUV malosi maualuga lasers gaosiga mo tioata ma CFRP.So'otaga

Moon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., & Kim, K.-S. (1999). Fa'aluaina lelei o le fa'aogaina o le intracavity frequency mai se diffusive reflector-type diode side-pumped Nd:YAG laser e fa'aaoga ai se KTP crystal.So'otaga

Salminen, A., Piili, H., & Purtonen, T. (2010). O uiga o le malosi maualuga fiber leisa uelo.Fa'agasologa o le Fa'alapotopotoga o Inisinia Mekanika, Vaega C: Journal of Mechanical Engineering Science, 224, 1019-1029.So'otaga

Majumdar, J., & Manna, I. (2013). Folasaga i le Faia o Meafaitino e Fesoasoani i le Laser.So'otaga

Gong, S. (2012). Su'esu'ega ma fa'aoga o tekinolosi fa'atekonolosi fa'atekonolosi fa'atekonolosi laser.So'otaga

Yumoto, J., Torizuka, K., & Kuroda, R. (2017). Atina'eina o se Moega Su'ega ma se Fa'amaumauga o Meafaitino Fa'a-Leisa mo le Fa'agasologaina o Mea Fa'a-Leisa.O le Iloiloga o le Inisinia o le Laser, 45, 565-570.So'otaga

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). O le alualu i luma i tekinolosi mata'ituina i totonu mo le gaosiga o le laser.SCIENTIA SINICA Physica, Mechanica & Astronomica. So'otaga

Sun, H., & Flores, K. (2010). Su'esu'ega Fa'aeletoronika o se Tioata U'amea Tele e Fa'avae i le Zr ua Fa'agasolo i le Laser.Fefa'ataua'iga Fa'ametala ma Meafaitino A. So'otaga

Nowotny, S., Muenster, R., Scharek, S., & Beyer, E. (2010). Sela laser ua tu'ufa'atasia mo le fa'apipi'iina o le laser ma le milling.Fa'aputuga Fa'aautomatika, 30(1), 36-38.So'otaga

Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., & Rao, BT (2013). Metotia Fou o le Fa'agasologa o Meafaitino Laser mo Fa'aoga Fa'apisinisi i le Lumanai.So'otaga

Hwang, E., Choi, J., & Hong, S. (2022). O faiga fou o le masini e fesoasoani i le masini e fa'amama ai le ea i le laser mo le gaosiga sa'o ma maualuga le fua.Nanoscale. So'otaga

Taimi na lafoina ai: Ianuari-18-2024